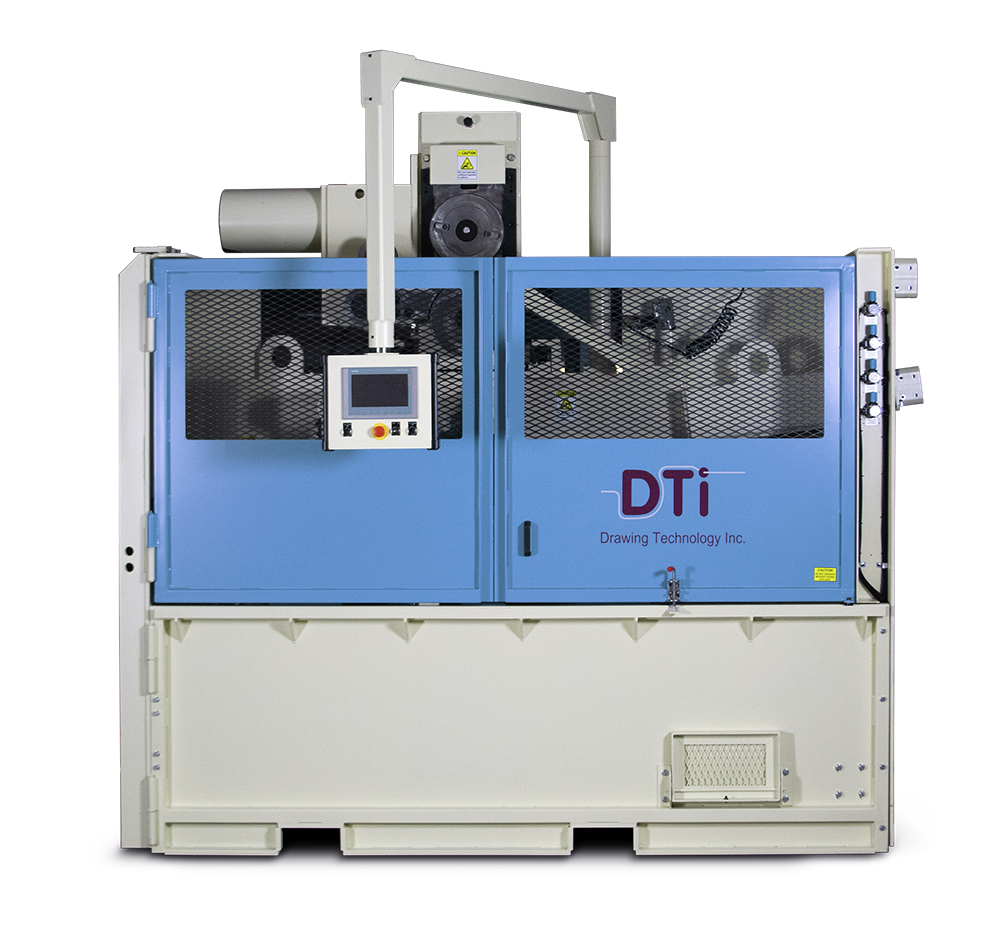

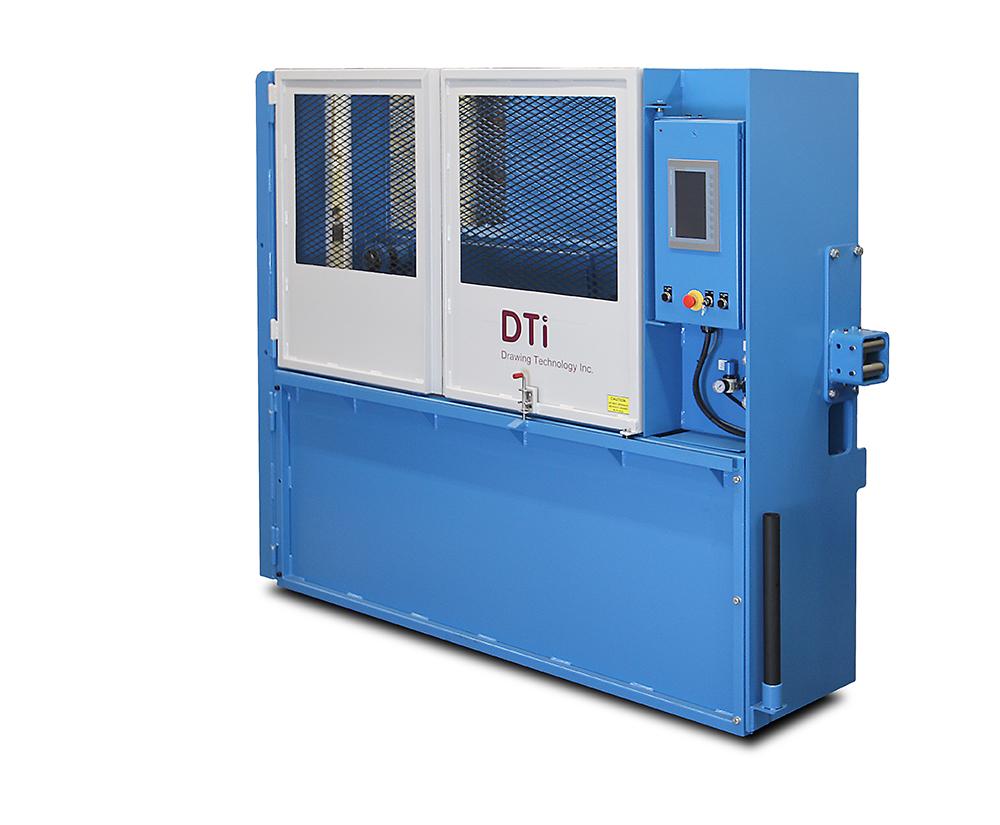

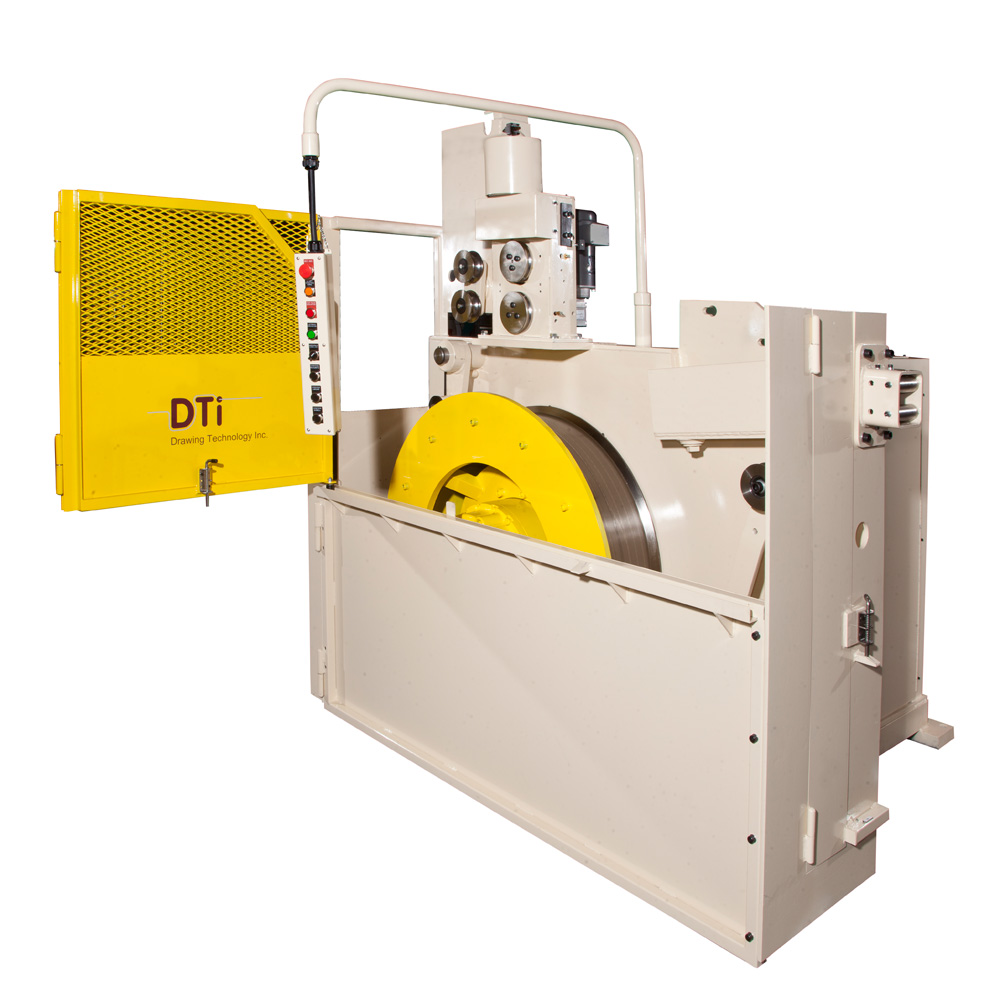

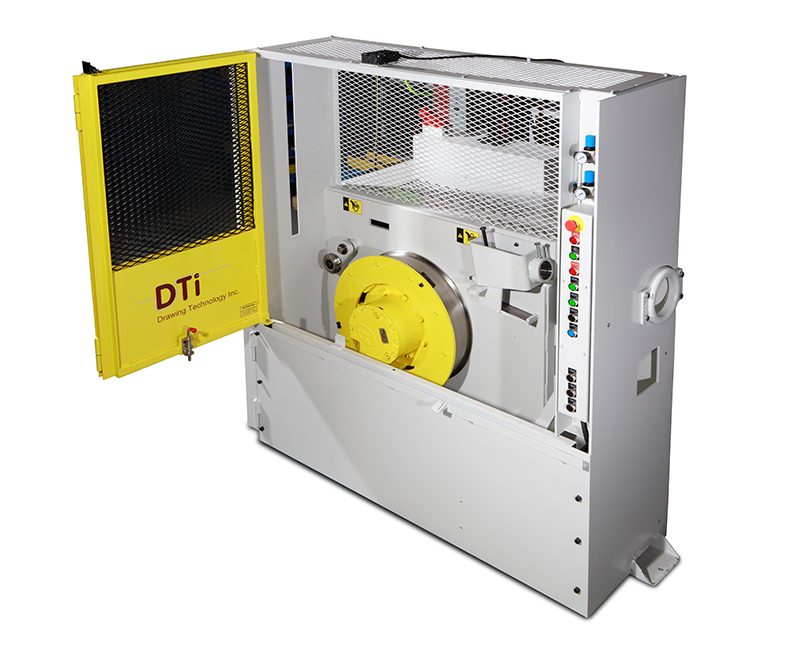

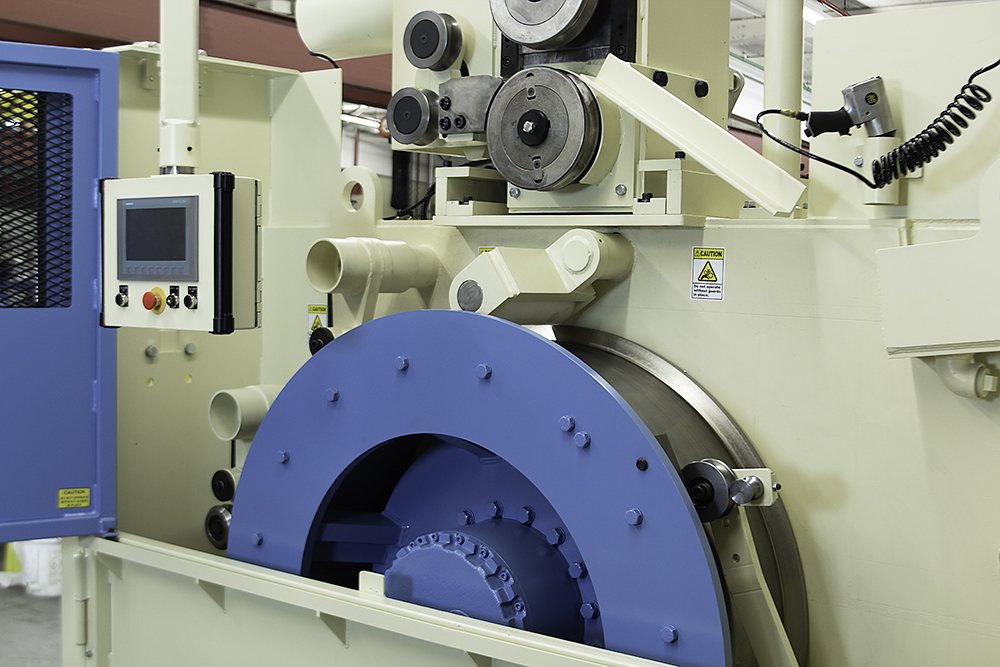

DTi is dedicated to produce the highest quality in-line wire drawing equipment and related accessories. Designed and built by the most experienced team in the industry, we are committed to the principals of high-quality construction, service excellence, machine safety, innovative design, and technical leadership.

STANDARD FEATURES

Compare closely, many of our standard features are only offered as additional cost items on our competitors machines, if available at all.

Capstan Diameters

Another subtle but possibly important difference is our capstan diameters. We make our capstans at true working diameter. If you buy a 20″ machine, the working diameter is 20″, not 19.09″ (5′ circumference our competitor uses). It is true of most of the larger capstans as well. This can make a huge difference when running at the upper limits of a machine or in high alloy material.

*Note: If viewing on a mobile device, details can be seen by scrolling the chart vertically.

| Model | Capstan Diameter inch [mm] | Max. Rated Draw Force lbs. [kg] | Alloy Max. Diameter inch [mm] | Mild Steel Max. Diamter inch [mm] | Available Horse Power Range hp [kw] | Feed Head |

| Model 12 | 12” [304] | 1200 [400] | .040 [1.0] | .125 [3.0] | 2 [1.4] | N/A |

| Model 31 | 20” [508] | 3100 [1406] | .250 [6.4] | .312 [8.0] | 5-20 [3.7-15] | N/A |

| Model 38 | 24” [610] | 5000 [2270] | .312 [7.9] | .375 [9.5] | 5-20 [3.7-15] | N/A |

| Model 43 | 28” [711] | 6500 [2950] | .375 [9.5] | .437 [11.0] | 10-60 [7.5-45] | N/A |

| Model 58 | 36” [914] | 8500 [3850] | .500 [12.7] | .580 [14.7] | 15-30 [11-22.5] | N/A |

| Model 63 | 36” [914] | 12500 [5660] | .562 [14.3] | .625 [16.0] | 20-60 [15-45] | OPTIONAL |

| Model 73 | 44” [1118] | 16000 [7250] | .688 [17.5] | .750 [19.0] | 25-75 [19-56] | OPTIONAL |

| Model 90 | 44” [1118] | 20000 [9060] | .750 [19.0] | .900 [22.9] | 30-100 [22.5-75] | STANDARD |

| Model 100 | 54” [1372] | 25000 [11300] | .875 [22.0] | 1.00 [25.4] | 30-200 [22.5-150] | STANDARD |

| Model 118 | 54” [1372] | 25000 [11300] | 1.00 [25.4] | 1.187 [30.0] | 30-200 [22.5-150] | STANDARD |

| Model 138 | 65” [1372] | 35000 [15820] | 1.125 [28.5] | 1.375 [34.925] | 30-200 [22.5-150] | STANDARD |

| Model 150 | 65" [1650] | 40000 [18144] | 1.125 [28.5] | 1.50 [38] | 30-200 [22.5-150] | STANDARD |

MODELS