DTI is dedicated to producing the highest quality payoff equipment. Designed and built by the most experienced team in the industry, we are committed to the principles of high-quality construction, service excellence, machine safety, innovative design, and technical leadership.

POWER UNCOILERS

• Can be equipped with twin coil support mandrels designed to reduce coil swing to allow for faster production speeds

• AC Inverter drive system

• Pneumatically actuated feed rolls, 8 or 12 inch (203 or 304 MM)

• Portable operator’s station

• HMI operator controls

• Ridged I beam construction to support the largest available coils

• 90- and 96-inch (2286 mm and 2438 mm) mandrels standard, other lengths available

• Snag detector switch

• Full enclosure, with safety interlocked guard available

• Power cutoff saw

• Integrated single or double plane straighteners

• End of coil detector

• Machine risers to adapt to non-standard wire lines heights

COIL FEEDER

Designed for high speed applications for diameters from .625”(16mm) to 1.5”(38mm). Eliminate the danger of operator injuries caused by pulling the end of the coil out by hand.

• Pull the end of the coil to the feed rolls and straightener using a simple gripper and winch system.

• Ideal for green rod applications

• Can be used with: Bull block, Draw bench, Pointer, Rotary swager, Welder, In-line wire drawer, Cold header, Straighten and cut machine

• Portable operators’ station

• Track mounting to move the machine out of the wire line

TURNTABLES

Power turntables

• AC inverter variable speed drive with dynamic braking

• Adjustable tension and height spring loaded dancer arm

• 50- and 60-inch diameter top plate (1270 and 1524 MM)

• 5000 lb. coil capacity (2265 KG)

• Wire containment ring

• Reversible rotation

• Production machine safety interlock system

• Dual speed control. Full dancer arm control or master setting with trim.

• Standard with mounting pads for up to 3 lifter arms

• Top plate sizes from 30 to 60-inch diameter (762 to 1524 MM)

• Heavy duty Timken bearing construction

• Coil weights up to 7000 pounds (3171 KG)

• Fixed 18 X 18-inch center spiders (457 x457 MM) Other sizes available

Passive turntables

• Wire containment ring.

• Pneumatic or mechanical drag brakes

• Adjustable and special center spiders

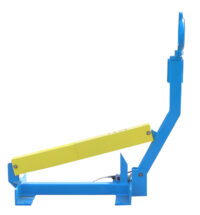

FLIPPERS

• Allows for coil changes without stopping the production line when used with a butt welder

• Handle coils sizes of up to 6000 pounds (2718 KG) with an unbanded length up to 8 feet (2.4 M)

• Can be used for rod sizes from .218 to .680 inch diameter (5.5 to 17mm)

• Space saving Z or S configurations standard

• Large radius saddles available to help reduce tangles on small diameter rod

SNAG DETECTOR SYSTEM

• Detects tangles and stops production line before the wire breaks

• Cuts down time associated with butt welding the broken wire or restringing the wire drawer

• Adaptable to most any draw line

• Adjustable tripping sensitivity

HYDRAULIC PULL POINTER

The hydraulic pull pointer reduces coil change time on large diameter wire drawing applications. Coil changes can be done without using a welder. Dies are pulled off the end of the wire so no trimming is needed before insertion into the draw die.

• 0.400 (10mm) to 1.375 ( 35mm) capacity

• Hydraulic power pack with lever-operated controls

• Can be mounted to a power uncoiler, power feeder or wire drawer, or on a roll-around cart

• Safety-guarding with interlock

• One set of tools included with machine

Model 138